Automotive industry

InfiPoints

Digital Factory (Digital Factory) will the product whole life cycle, on the basis of the data in a computer environment, for the whole production process, process simulation, evaluation and optimization, with advanced Digital manufacturing technology and computer simulation application product of mutual integration, to provide new thinking and method for basic manufacturing, reduce the problems of communication between product design and product manufacturing, and shorten the development cycle and cost of the product, realize simulation of virtual manufacturing and 3 d virtual reality visualization.

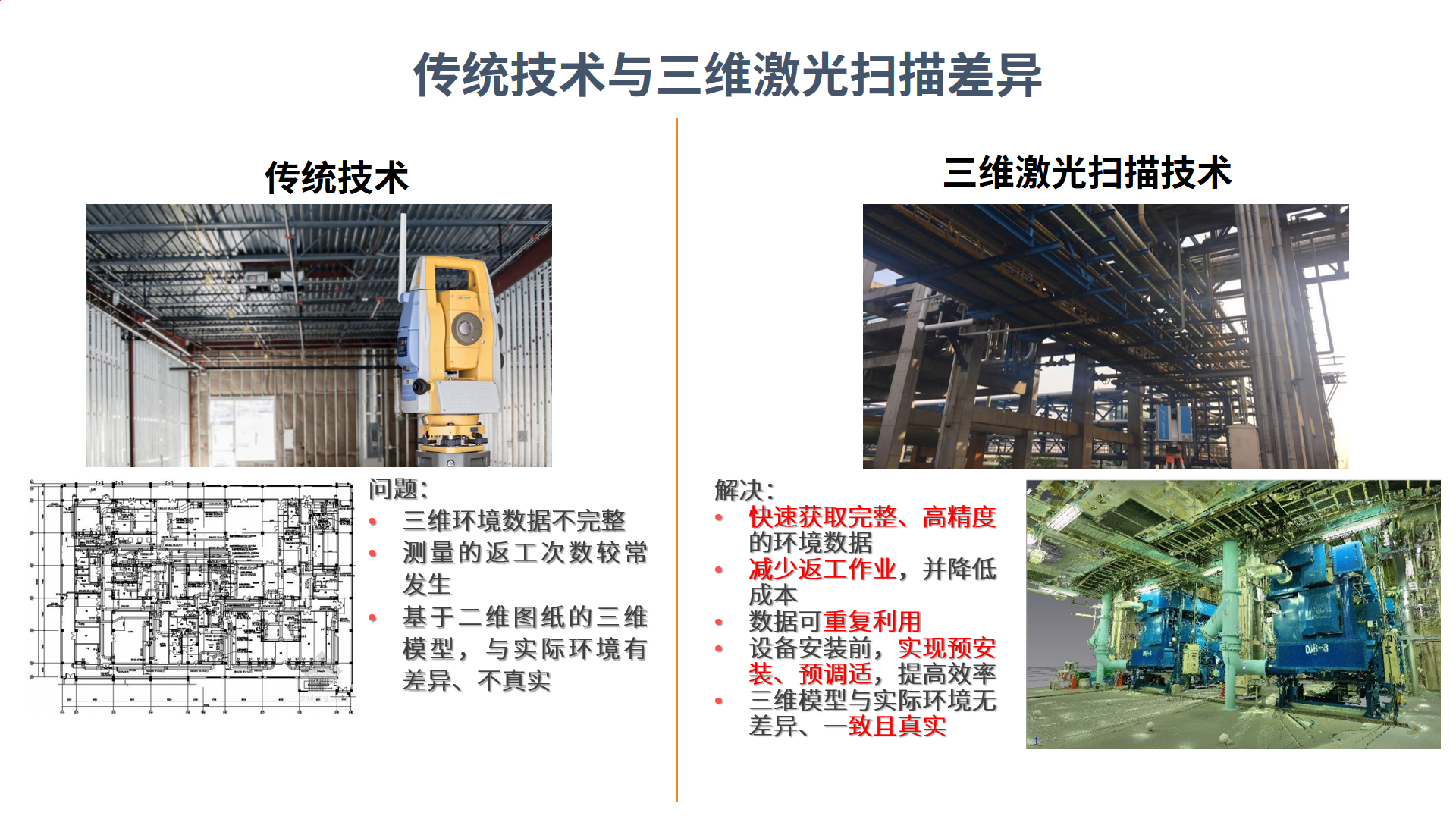

In car manufacturers of digital process, this process is called "digital manufacturing environment," we need to the whole factory's digital car factory, the traditional measuring method in the complex plant measure, can cause very big workload, and will miss many important details, some curved surface, cylindrical structure is unable to use traditional measurement to obtain accurate measurement data.

3d laser scanning technology can make us more convenient, fast and accurate to build the 3d model of the whole factory.This technology can completely obtain high precision and wide range of 3d scanning data.It only takes a very short time to obtain the 3d scan data of the plant.The following is a partial scan of the production line of an automobile factory.

Scanning data application

1. Automatic extraction of 3d model from scanning data (Honeywell Facility,Eaton Facility)

2. Equipment layout planning

3. Transform transportation path simulation

Digital Factory (Digital Factory) will the product whole life cycle, on the basis of the data in a computer environment, for the whole production process, process simulation, evaluation and optimization, with advanced Digital manufacturing technology and computer simulation application product of mutual integration, to provide new thinking and method for basic manufacturing, reduce the problems of communication between product design and product manufacturing, and shorten the development cycle and cost of the product, realize simulation of virtual manufacturing and 3 d virtual reality visualization.

In car manufacturers of digital process, this process is called "digital manufacturing environment," we need to the whole factory's digital car factory, the traditional measuring method in the complex plant measure, can cause very big workload, and will miss many important details, some curved surface, cylindrical structure is unable to use traditional measurement to obtain accurate measurement data.

3d laser scanning technology can make us more convenient, fast and accurate to build the 3d model of the whole factory.This technology can completely obtain high precision and wide range of 3d scanning data.It only takes a very short time to obtain the 3d scan data of the plant.The following is a partial scan of the production line of an automobile factory.

Scanning data application

1. Automatic extraction of 3d model from scanning data (Honeywell Facility,Eaton Facility)

2. Equipment layout planning

3. Transform transportation path simulation

Related Cases

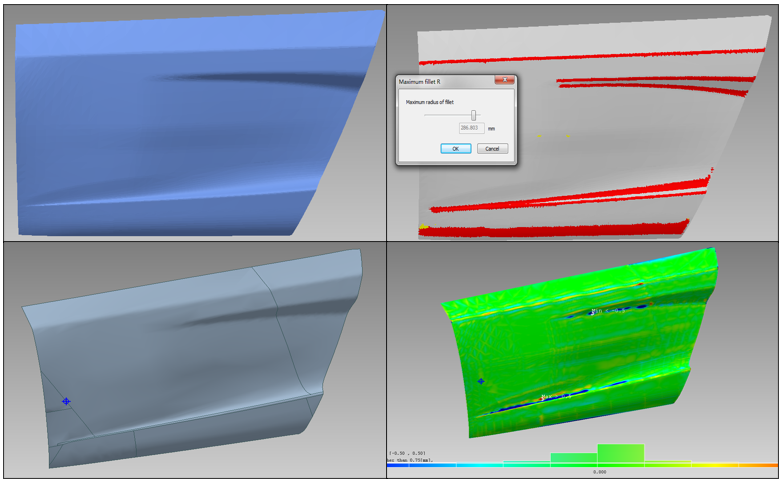

The competitive product analysis department of the customer scans the ..

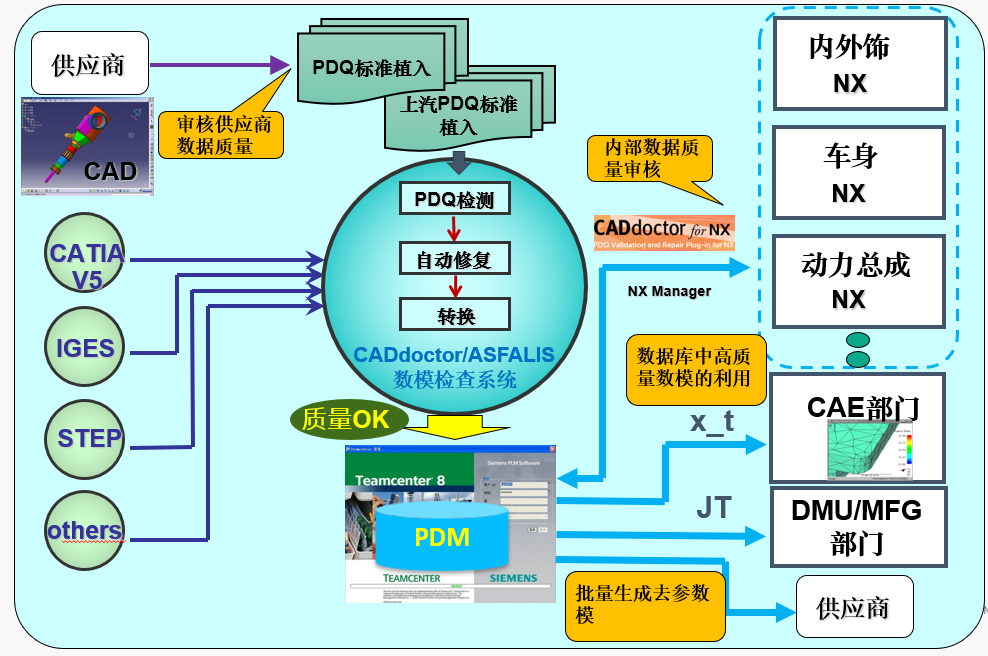

By using ASFALIS inspection system, a famous domestic OEM optimize..

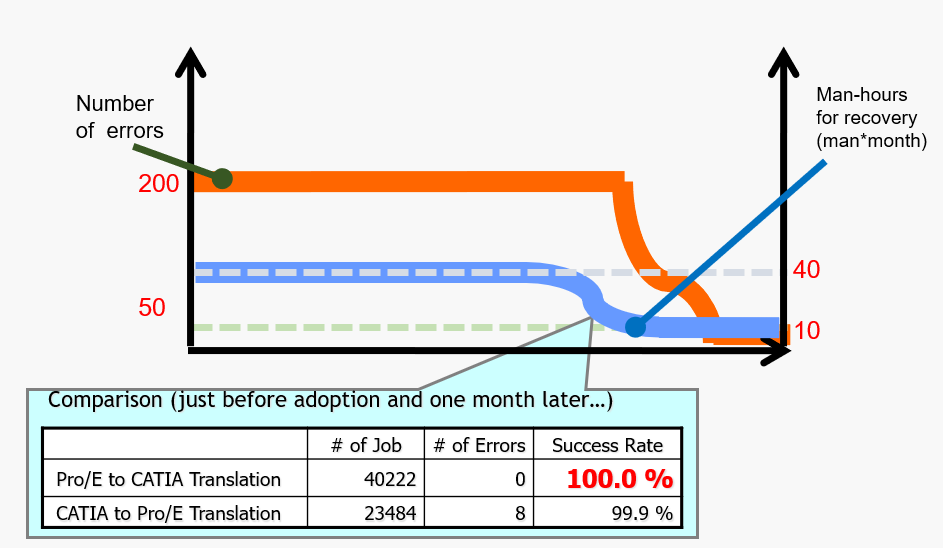

A world famouse OEM sets up control nodes for internally developed..