Automotive industry

One day at a trade show, Professor Kuma met 3D laser scanner and point cloud handling software, InfiPoints, which provides a functionality to extract the ground surface from the obtained point cloud data. He quickly introduced a new method to his research — 3D scans the remains of mines, and then extract the points for the ground surface from the obtained point cloud data using InfiPoints.

Extracting the points for ground surface only using InfiPoints

Point cloud data of Hyotan drift mine, Tada Silver-and-Copper Mine

He investigated one of the most valuable mines, Tada Silver-and-copper Mine, using this new method, and successfully identified the mark of open-pit mining, a characteristic surface mining technique.

Moreover, he optimized the 3D scanned data for 3D printing using InfiPoints, and created a model of remain of the mine for further investigation — estimated the total amount of silver production from the volume of the mark of open-pit mining.

Left: Polygons generated from optimized point cloud data

Right: Model made by 3D printer

Left: On-site investigation of stone walls in Tada Silver-and-Copper Mine

Right: Polygon data of ground surface generated from 3D scanned data — stone walls came out clearly by removing points for woods in InfiPoints

One day at a trade show, Professor Kuma met 3D laser scanner and point cloud handling software, InfiPoints, which provides a functionality to extract the ground surface from the obtained point cloud data. He quickly introduced a new method to his research — 3D scans the remains of mines, and then extract the points for the ground surface from the obtained point cloud data using InfiPoints.

Extracting the points for ground surface only using InfiPoints

Point cloud data of Hyotan drift mine, Tada Silver-and-Copper Mine

He investigated one of the most valuable mines, Tada Silver-and-copper Mine, using this new method, and successfully identified the mark of open-pit mining, a characteristic surface mining technique.

Moreover, he optimized the 3D scanned data for 3D printing using InfiPoints, and created a model of remain of the mine for further investigation — estimated the total amount of silver production from the volume of the mark of open-pit mining.

Left: Polygons generated from optimized point cloud data

Right: Model made by 3D printer

Left: On-site investigation of stone walls in Tada Silver-and-Copper Mine

Right: Polygon data of ground surface generated from 3D scanned data — stone walls came out clearly by removing points for woods in InfiPoints

Related Cases

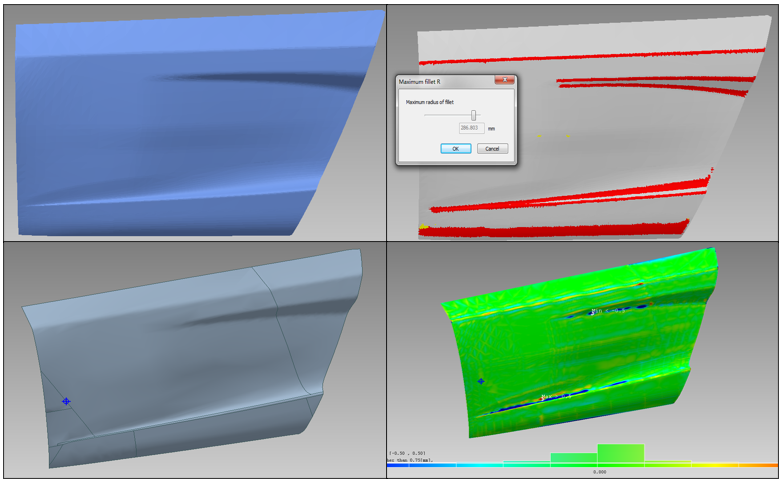

The competitive product analysis department of the customer scans the ..

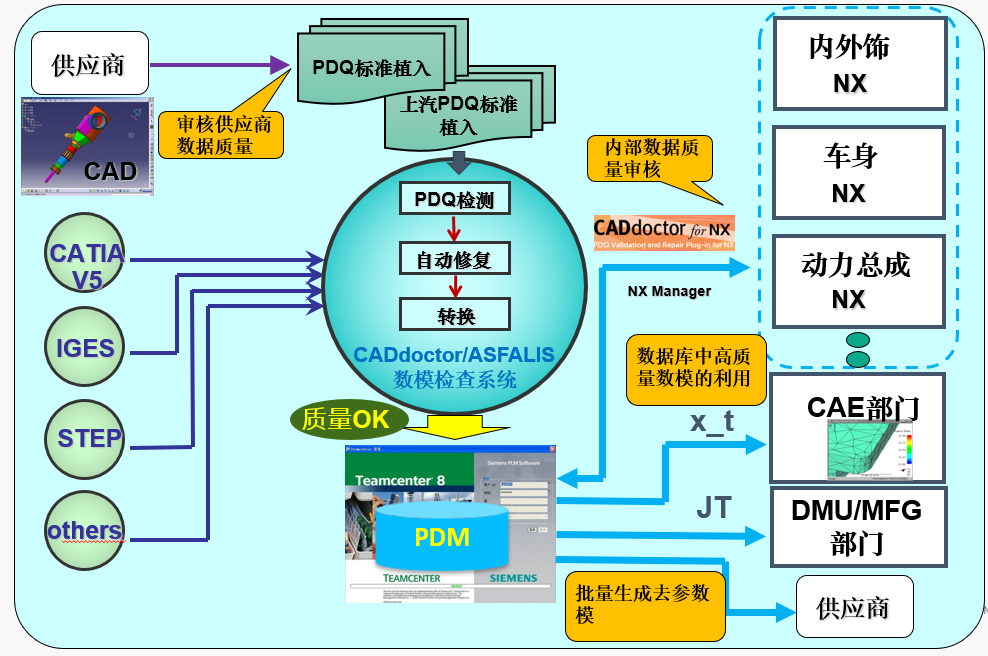

By using ASFALIS inspection system, a famous domestic OEM optimize..

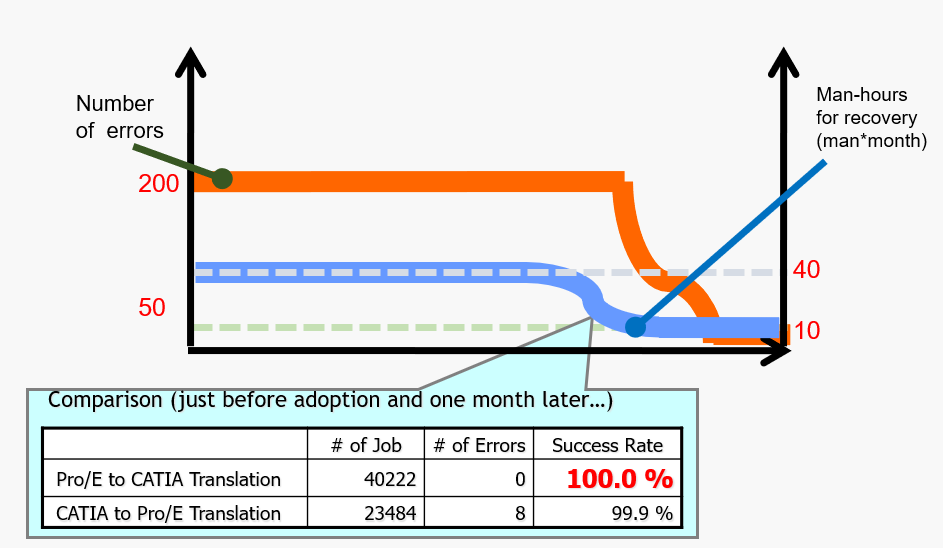

A world famouse OEM sets up control nodes for internally developed..