Other industries

InfiPoints

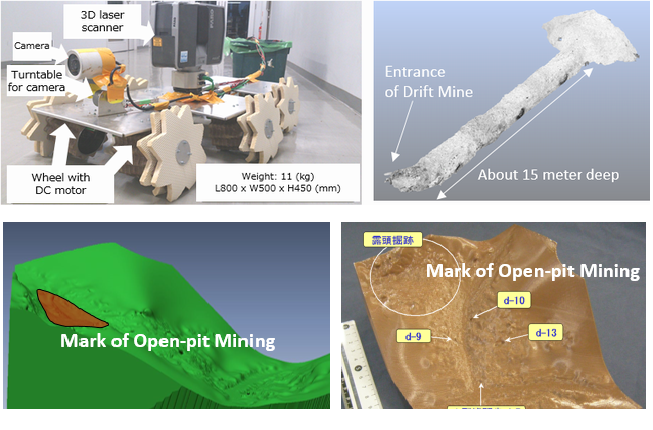

Professor Huma Kuma, from the department of control engineering at the National Institute of Technology Matsue College, developed and developed a new method of detection -- using 3D scanning equipment and specially developed remote-controlled robots to go deep into the narrow mine, 3D scanning the ground near the mine and the entrance, and estimating the opening time and output of the drifting mine.

An investigation into the historical value of silver mines

Japan has many heritage sites throughout the country, including the rocky silver mountain silver mine, which was recognized as a UNESCO world heritage site in 2007. Due to its historical value, nearly one-third of silver was spread around the world in the 16th century and beyond.However, these mines are now well wooded and access to the site is often limited by the risk of rock falls, making it difficult to get to the site, or even to obtain complete images and conduct detailed investigations.Therefore, the study mainly used sketches and photographs to record the exterior of the mine.Some units tried to carry out 2D scanning in the mine, but the data obtained was not accurate enough to satisfy the survey operation.

3D scanning ground - automatically extracts ground and removes point cloud data from trees

At the exhibition one day, professor Kuma came across a 3D laser scanner and InfiPoints, a point cloud processing software, which provides the function of extracting ground points from the obtained point cloud data.He quickly introduced a new research method -- 3D scanning of mine relics, and then used InfiPoints to extract the point cloud of the surface from the obtained point cloud data.Using this new method, he investigated one of the most valuable mines, the tada silver and copper mine, and successfully identified the hallmark of open-pit mining, a special surface mining technique.In addition, he also used InfiPoints to optimize 3D scan data for 3D printing, and created the remaining mine model for further investigation - estimated the total production of silver mine from the total mining amount of open-pit mining.

Automatic noise reduction

Drift mines are often physiologically confined, and even if possible, it is still difficult to Drift for more than a few hours in narrow, dusty Drift mines.Special robots developed by students in professor Kuma's office can perform unattended 3D scans in drifting mines.InfiPoint is used for the preprocessing of point cloud data -- faster data splicing, and the filtering of dust and noise caused by internal mines. 3D scanning data is fully utilized in their actual investigation and research.

The possibility of applying point cloud processing technology to disaster prevention

Kuma, who has examined more than 100 Drift mines across Japan, says it is possible to use 3D scanning and point-cloud technology for disaster prevention, for example by monitoring hillsides regularly to detect changes in landslide risk.

Professor Huma Kuma, from the department of control engineering at the National Institute of Technology Matsue College, developed and developed a new method of detection -- using 3D scanning equipment and specially developed remote-controlled robots to go deep into the narrow mine, 3D scanning the ground near the mine and the entrance, and estimating the opening time and output of the drifting mine.

An investigation into the historical value of silver mines

Japan has many heritage sites throughout the country, including the rocky silver mountain silver mine, which was recognized as a UNESCO world heritage site in 2007. Due to its historical value, nearly one-third of silver was spread around the world in the 16th century and beyond.However, these mines are now well wooded and access to the site is often limited by the risk of rock falls, making it difficult to get to the site, or even to obtain complete images and conduct detailed investigations.Therefore, the study mainly used sketches and photographs to record the exterior of the mine.Some units tried to carry out 2D scanning in the mine, but the data obtained was not accurate enough to satisfy the survey operation.

3D scanning ground - automatically extracts ground and removes point cloud data from trees

At the exhibition one day, professor Kuma came across a 3D laser scanner and InfiPoints, a point cloud processing software, which provides the function of extracting ground points from the obtained point cloud data.He quickly introduced a new research method -- 3D scanning of mine relics, and then used InfiPoints to extract the point cloud of the surface from the obtained point cloud data.Using this new method, he investigated one of the most valuable mines, the tada silver and copper mine, and successfully identified the hallmark of open-pit mining, a special surface mining technique.In addition, he also used InfiPoints to optimize 3D scan data for 3D printing, and created the remaining mine model for further investigation - estimated the total production of silver mine from the total mining amount of open-pit mining.

Automatic noise reduction

Drift mines are often physiologically confined, and even if possible, it is still difficult to Drift for more than a few hours in narrow, dusty Drift mines.Special robots developed by students in professor Kuma's office can perform unattended 3D scans in drifting mines.InfiPoint is used for the preprocessing of point cloud data -- faster data splicing, and the filtering of dust and noise caused by internal mines. 3D scanning data is fully utilized in their actual investigation and research.

The possibility of applying point cloud processing technology to disaster prevention

Kuma, who has examined more than 100 Drift mines across Japan, says it is possible to use 3D scanning and point-cloud technology for disaster prevention, for example by monitoring hillsides regularly to detect changes in landslide risk.